Paint Machinery

Chemical Machinery

Resin Manufacturing Plants

Pharmaceutical Machinery

Unsaturated Polyester Resin Production Line, Resin reactor

1:Unsaturated Polyester Resin Production Line 2:Material:SS/CS 3:Application:UP Resin,Epoxy Resin,Alkyd Resin,Phenolic Resin

UP Resin Production Line(from Laboratory Scale to Mass Production)

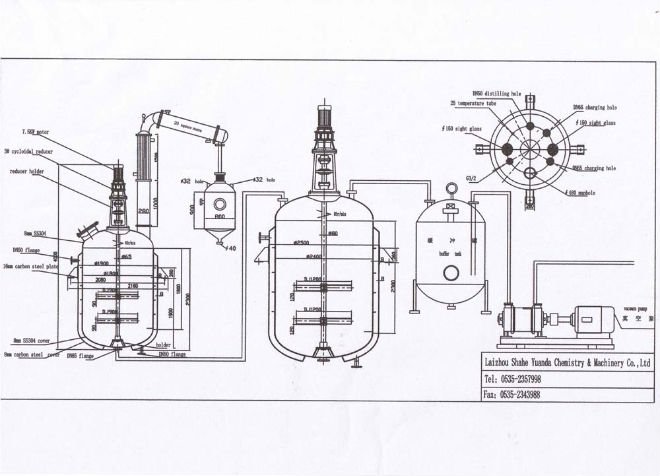

Mainly including Reactor,Dilute kettle,Oil-water separator,Buffer tank,Condenser etc.

Can be widly used in :Unsaturated Polyester Resin,Alkyd Resin,Fiberglass Resin,Artificial Marble Resin,Epoxy Resin,Phenolic Resin etc.

Heating way can be:Electric Heating,Steam Heating,Thermal Oil Heating etc.

Different Capacity from Laboratory Scale to Mass Production is provided ,welcome all customers come to inquire!

Below is Details of 10 Tons/batch Unsaturated Polyester Resin Production Line for your reference:

A:5000L Reactor Configuration:

1)Motor power: 11kw

2):Inner material and thinkness:304 stainless steel plate. 10mm

3)Outher material and thickness:Carbon steel 8 mm

4)Heating way:Thermal Oil Heating(Natural Gas as fuel)

5):Cooling system: §50 internal dish tube×8 laps(304 stainless steel)

6):Speed:65 RPM((with 4 # Cycloidal Gear reducer 65 RPM)

B:10000L dilute kettle configuration

1)Motor Power: 15 kw

2):Inner material and thickness:304 stainless steel 10mm

3) Outer material and thickness:carbon steel 10mm

C:Horizontal Condenser:20 Square Meter (304 Stainless steel)

D:Vertical Condenser:1000mm(Height/piece)*280mm(Diameter)

(2 Pieces) E:Oil-water Separator:800 L (304 Stainless steel)

F:Buffer Tank:500 L(Carbon steel).

Polyester Resin Plants

(Saturated Polyester Resin Plant – Powder form)

(Un-Saturated Polyester Resin Plant – Liquid form)

The major operations involved in the manufacture of polyester resin are esterfication and blending – which are carried in their respective kettles. The most common raw materials used are polypropylene glycol, melic anhydride and styrene monomer. In addition small quantities of inhibitors and other additives are required for the process.

The process involved is poly condensation reaction and blending the polyester resin with the monomer. Due to the sensitivity of polyester resin to contamination; in the course of condensation reaction and during subsequent handling the material of construction must be carefully selected.

Resin Plant Type

| Unsaturated polyester resin production plant | UP Resin Production Line | powder mixer machine |

| alkyd resin reactor | powder blender | industrial powder mixer |

| resin reactor | polyester resin production | high speed mixer granulator |

| high speed powder mixer | Unsaturated Polyester Putty | liquid dispersing machine |

| unsaturated polyster resin machine | resin production line |

chemical disperser |