High Speed Dispersers are considered as most versatile equipment for paint production. As the name suggests, the disperser range has been specifically designed to disperse, mix and homogenize products.

The process of dispersion is carried out by the centrally located shaft having Saw tooth impeller & running at high speed (1000 to 1400 RPM). Reckoned for trouble-free operations, the equipment made available in this range is extensively used for manufacturing plastic emulsions, solvent based Paints and eco-friendly water based paints.

High-speed Disperser is to dissolve, disperse and mix materials with different viscosity. Through the very high peripheral tip speed of the toothed disc, the strong shearing, crashing and friction forces generated between the materials and toothed disc disperse, dissolve and mix the materials efficiently. The large stress forces break down the agglomerates into the liquid or paste suspension.

High Speed Dissolver for Printing Ink Mixing

High Speed Dissolver for Printing Ink Mixing

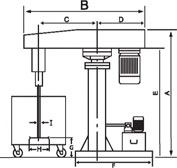

Variable High Speed Dissolver of ____ Ltrs capacity driven by a __ HP TEFC motor installed on a top head drive complete with mechanical variable speed pulley to vary RPM from 500 - 2400, Ideal pulleys, bearings and other accessories. The head is fabricated out of heavy M.S. plates and sections to keep vibrations to the minimum. The entire drive assembly is mounted on a vertical hydraulic column provided with a hydraulic cylinder to lift the head upto a clear height of 1 meter. The Dissolver shaft is installed in a steel housing complete with bearings and seals for smooth and leak proof operation. The shaft is dynamically and statically balanced alongwith the cowless Dissolver blade. A hydraulic power pack unit is provided to lift and lower the Dissolver. The unit consists of a Hydraulic cylinder complete with a ___ HP Electric motor, relief valve, control valve, oil tank, Hose pipe and other fittings. A mechanically hand operated vessel locating and locking device is provided to centrally locate the vessel.

Features :

- Optimum Process Selection of Mixer for Motor Power at given Tip Speed

- Solid shafts for strength and ease of handling for HSD

- Excellent Shaft machining in order to Control the Shaft run-outs, vibration and noise

- Use of external bearing housing with back to back Tapper Roller bearing

- Rugged and Robust mounting structure for strength and durability

- Hydraulic Lifting System for HSD is Optionally available

- Epoxy Paint finish as Standard

MODEL |

MAIN MOTOR |

LIFTING MOTOR |

SPEED RANGE |

INTER CHANGEABLE DISC |

WEIGHT |

SHELL TOTAL CAPACITY |

ABFHSD 7.5 |

7.5 |

1 |

800-1500 |

150-200 |

600 |

250 |

ABFHSD 10 |

10 |

1 |

800-1500 |

150-200 |

600 |

250 |

ABFHSD 15 |

15 |

1 |

800-1500 |

15s0-200 |

625 |

375 |

ABFHSD 25 |

25 |

2 |

535-1500 |

250-285 |

1000 |

700 |

ABFHSD 30 |

30 |

2 |

535-1500 |

250-285 |

1100 |

800 |

ABFHSD 40 |

40 |

2 |

370-1200 |

325-390 |

1500 |

1000 |

ABFHSD 50 |

50 |

2 |

370-1200 |

325-390 |

1700 |

1250 |

High speed paint dispersing mixer, High speed disperser/dissolver,High Quality high speed disperser,high speed disperser, high speed disperser, high speed mixers suppliers, industrial mixers, mixing equipment, industrial mixing equipment, high speed dispersers

| Model | Motor HP (kW) | RC (Liter) < 4000 cps | RC (Liter) < 1500 cps | A | B | C | D | E | F | G | H | I | G+J | Weight (KG) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ABF-05E | 1/2HP (0.37) | 1-4 | 2-5 | 720 | 500 | 170 | 150 | 430 | 500 | 30 | 100 | 22 | 250 | 60 |

| ABF-105E | 1HP (0.75) | 10-30 | 15-40 | 1300 | 1200 | 450 | 250 | 750 | 700 | 100 | 150 | 30 | 500 | 120 |

| ABF-205E | 2HP (1.5) | 30-80 | 50-120 | 1500 | 1300 | 600 | 300 | 1300 | 700 | 150 | 150 | 30 | 600 | 160 |

| ABF-305 | 3HP (2.2) | 80-150 | 100-200 | 1750 | 1600 | 750 | 500 | 1350 | 1000 | 200 | 200 | 45 | 1000 | 700 |

| ABF-505 | 5HP (3.7) | 100-200 | 150-300 | 1900 | 1600 | 750 | 500 | 1350 | 1000 | 200 | 230 | 50 | 1000 | 800 |

| ABF-755 | 7.5HP (5.5) | 200-350 | 300-500 | 1900 | 2200 | 1000 | 600 | 1580 | 1000 | 200 | 250 | 50 | 1250 | 1400 |

| ABF-1010 | 10HP (7.5) | 300-400 | 400-600 | 1900 | 2200 | 1000 | 600 | 1580 | 1000 | 200 | 280 | 60 | 1250 | 1500 |

| ABF-1510 | 15HP (11) | 400-600 | 500-800 | 1900 | 2200 | 1000 | 600 | 1580 | 1000 | 200 | 300 | 60 | 1300 | 1600 |

| ABF-2010 | 20HP (15) | 500-800 | 800-1200 | 1900 | 2200 | 1000 | 600 | 1580 | 1000 | 200 | 330 | 60 | 1300 | 1700 |

| ABF-2510 | 25HP (18.5) | 800- 1200 | 1000-1500 | 2100 | 2500 | 1250 | 700 | 1700 | 1100 | 250 | 350 | 60 | 1400 | 2000 |